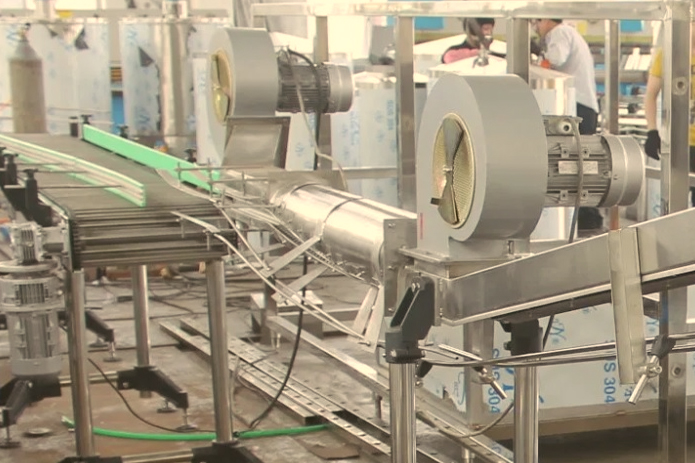

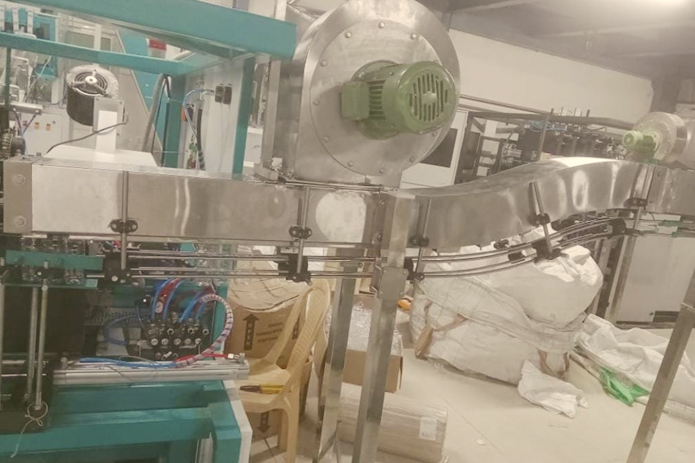

At Samarth Engineering, we manufacture, supply and trade various types of conveyors such as belt, air, chain conveyors along with associated product parts and components such as conveyor mounted air blower. We strive to maintain the high quality of our products by rationally utilizing resources and existing assets. Our ability to respond efficiently to customer demands while adhering to budget and given deadlines has earned us a good reputation in the market. We have an efficient team of technocrats who are adept at completing their duties within the stipulated time interval. As a leading manufacturer of high-quality air blowers specifically designed for conveyor applications, we offer a diverse range of solutions to meet your unique needs.

Air blowers play a crucial role in various types of conveyor systems, enhancing their efficiency and functionality in several ways:

1.Improved product movement: Samarth Engineering air blowers are engineered to provide reliable and efficient air flow, ensuring smooth and consistent product movement in your conveyor system.

2.Reduced downtime: By effectively removing debris and preventing material build-up, our air blowers help minimize maintenance requirements and downtime, keeping your operation running smoothly.

3.Versatility for diverse applications: We offer a comprehensive selection of air blowers suitable for pneumatic conveying, air conveyor systems, cleaning and maintenance, product sorting, and cooling/ventilation.

1.Meticulous craftsmanship: We utilize high-grade materials and rigorous manufacturing processes to ensure the durability and longevity of our air blowers.

2.Performance-driven design: Our air blowers are designed to deliver optimal airflow at the required pressure, ensuring efficient operation and energy savings.

3.Customization options: We understand no two conveyor systems are identical. That's why we offer customization options to tailor air blower specifications to your specific application requirements.

At Samarth Engineering, we are committed to providing exceptional customer service. Our team of experienced engineers is available to assist you in selecting the most suitable air blower for your conveyor system, ensuring optimal performance and maximizing your return on investment. Contact Samarth Engineering today to discuss your air blower needs and experience the difference of superior quality, reliable performance, and exceptional customer support.